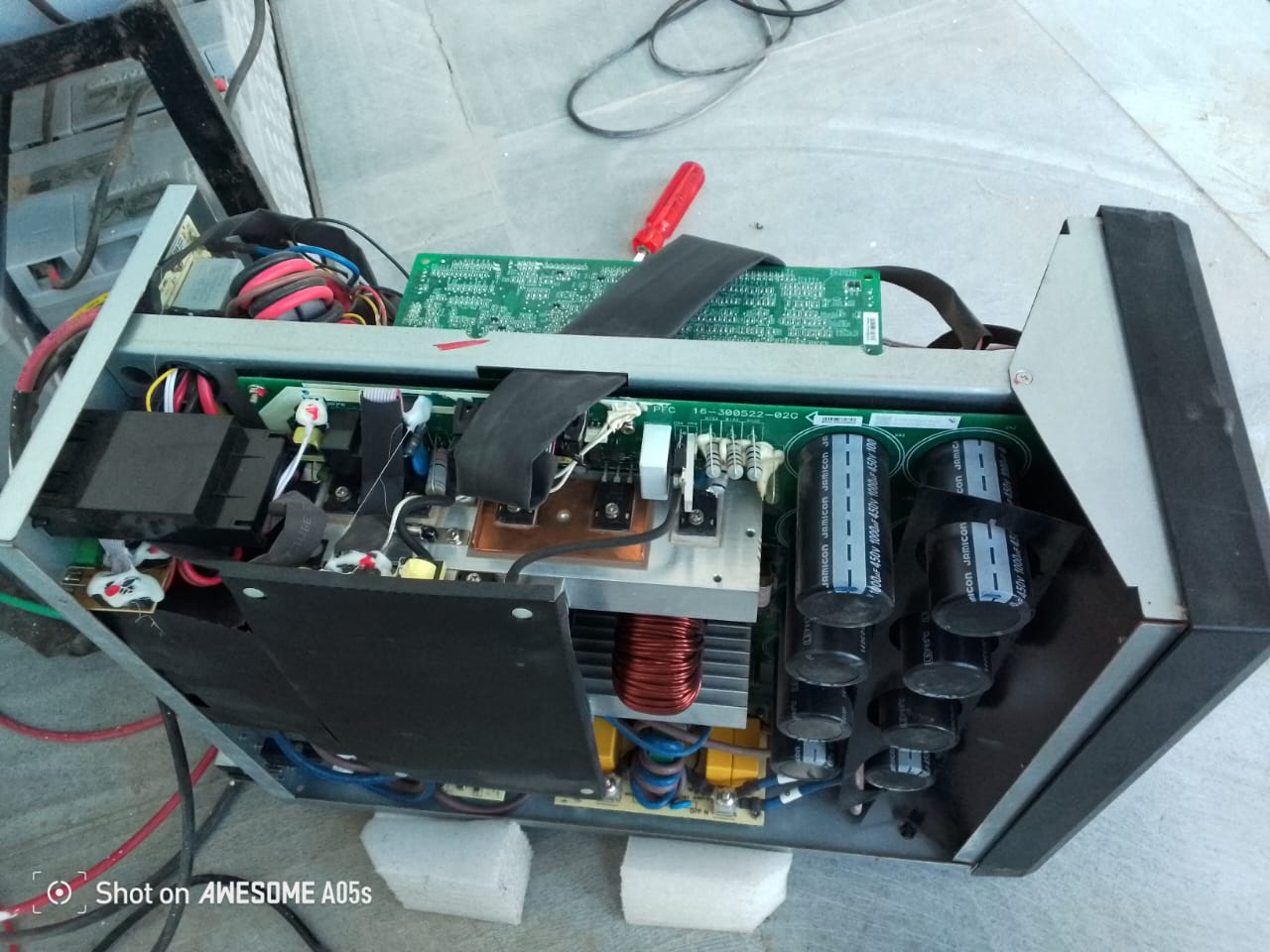

Online Ups Amc Repair & Services

As a leading provider of UPS services, we understand the criticality of uninterrupted power supply for your business. Our team of highly skilled technicians is dedicated to delivering efficient and reliable online UPS services in Gurgaon, Delhi, Noida, Bawal, Bhiwadi, Manesar, Sonipat , Faridabad .

With our expertise and experience, we offer comprehensive solutions for online UPS installation, maintenance, and repair. Whether you are looking for a new installation or need assistance with troubleshooting and repairs, we have got you covered.

UPS Repair & Services In Manesar

We specialize in UPS Repair & Services in Gurgaon, Delhi, Noida, Bawal, Bhiwadi, Manesar, Sonipat , Faridabad . offering professional troubleshooting and repair. Our team is equipped to handle issues of any scale, ensuring your UPS systems are always in top working condition.

Maintenance Contract

After entering into AMC, the contract will do the 1st preventive maintenance to check UPS condition, Healthy and working UPS only will be considered under AMC and also Faulty will be repaired on chargeable basis before considering it under AMC.

If the batteries are found faulty at the time of inspection it will have to be replaced before taking it under AMC.

Any make, any capacity (expect Vertiv & Emerson) Unlimited Break Down calls (Except Wire wound components, batteries, transformers).

Includes 100% labor and travel coverage 6 days/week, 8 hours/day.

Performed by ACCESS factory trained Customer Engineers.

Break down calls – UNLIMITED.

Subject to all Terms & Conditions as noted in the ACCESS Maintenance Agreement.

8 Hours Turnaround Time.

Preventive Service

Preventive Measurement : 4 PM per year Cleaning up of Unit, Visual Inspection tocheck any deformation.

Checking and Adjustment (If needed) of Power parameters like input. Output, DC voltage & Current.

Checking and Adjustment (If needed) of Control parameters on different PCBs.

Tightness of all connections, if shut down possible.

Functional Checking up of Rectifier section.

Functional Checking up of Inverter section.

Functional Checking up of Static Switch Section.

With customer approval, perform operational tests of the system including unit transfer and battery discharge.

Maintaining the posted checklist at the client place.

Battery Health checks with Multi Meter.

Battery AMC

Introducing for the very first time in the Industry “Battery AMC”, wherein you get your additional 3rd year warranty only @15% of your previous pay for the batteries.

Quanta Amaron Make of battery is only included in AMC.

Battery should be within the warranty period.

Currently AMC will be carried forward only for Gurgaon, Delhi, Noida, Bawal, Bhiwadi, Manesar, Sonipat , Faridabad . Region.

UPS Renting

Cost Effective: Rental UPS is very cost effective, you can save on huge project costs.

Power Stability: Provides stable power continuously and saves all your expensive equipment from Power Surges.

No Minimum Requirements: Online UPS available from 1KVA to 600 KVA on rent for short & long term.

No Maintenance Cost: UPS Rental helps you save on maintenance & Servicing cost.

Customisable: Special customization facility available for your specific needs.

No Power Cuts: Battery life is always ON, due to immediate replacement facility.

Maintenance Contracts

On line ups in each kVA rating and battery backup system are very sensitive issues and so it should be taken care utmost to enhance the life of UPS system and battery life for almost 99% up time during performance. Access Power Link is a leader in this market for 25 years having expertise and experience in the field to ensure hassle-free UPS AMC services on PAN INDIA level.

UPS Servicing To Suit You

Our response time is the time to get to site, not the time for a callback Travel and labour is included in all contract prices unless not required

Our technical support is offered by actual UPS experts, not a call centre.

Our inclusive parts contracts include ALL parts not just “consumables”.

Our preventative maintenance includes multipoint checks not just visuals.

We offer different plans to pass on savings during normal working hours.

Send

Message