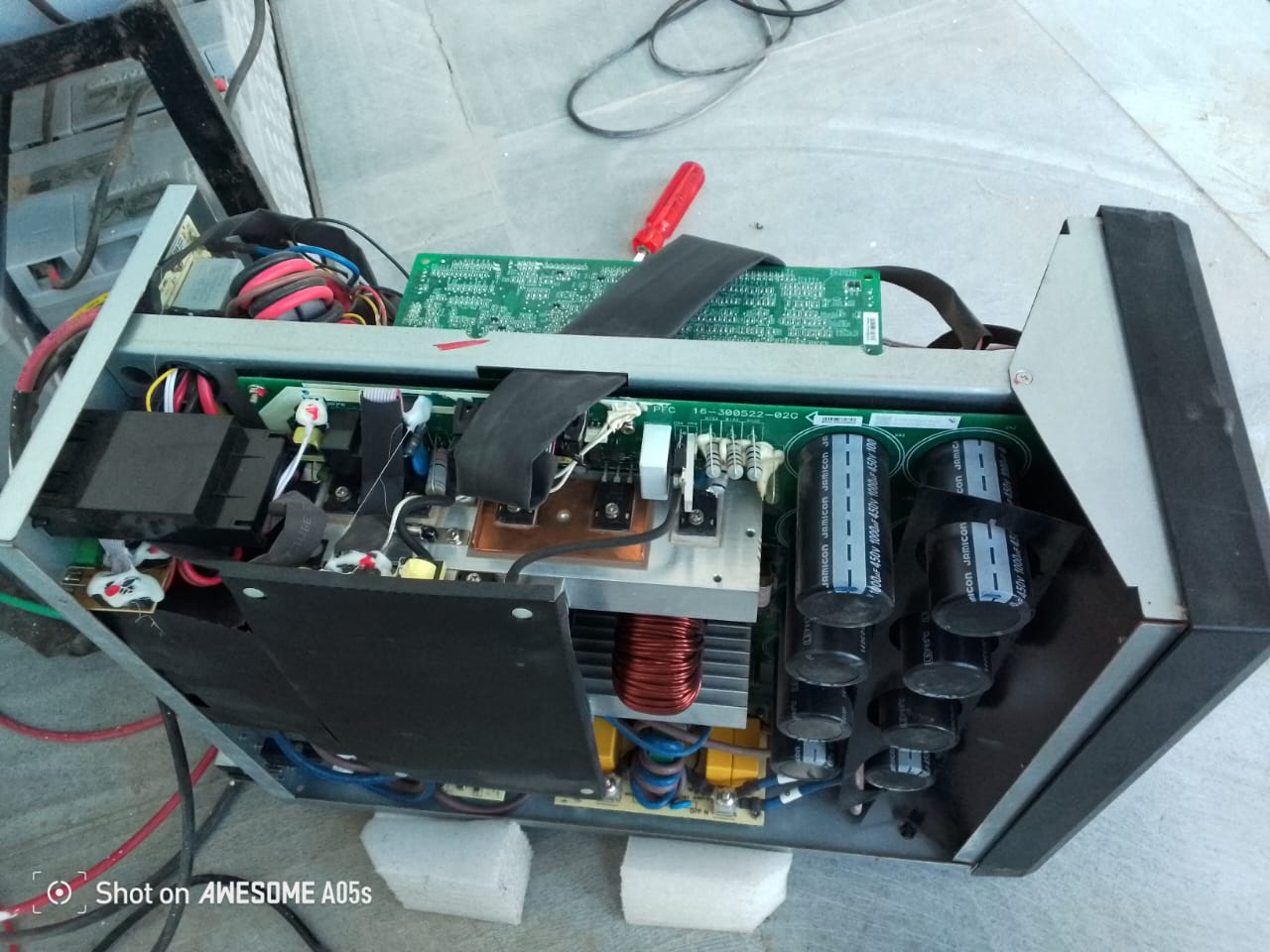

When it comes to Vertiv 10kVA UPS repair and testing, it involves several key processes to ensure that the UPS functions correctly and reliably. Below are the details regarding Vertiv 10kVA UPS repair and testing: Vertiv 10kVA UPS Repair Common Issues: Battery Failure: Batteries may degrade over time and need replacement. Inverter Problems: The inverter may fail to convert DC to AC power. Overheating: Excessive heat can damage internal components. Faulty Charging Circuit: Issues with the charging system can prevent batteries from charging properly. Software Failures: Problems with firmware can affect UPS functionality. Repair Process: Diagnosis: Use diagnostic tools to identify issues. Check for error codes or alerts on the UPS display. Component Testing: Test batteries for capacity and voltage. Inspect the inverter and charging circuits for faults. Replacement of Parts: Replace faulty batteries with new ones. Repair or replace damaged circuit boards, inverters, or other components. Calibration: Calibrate the UPS settings to ensure optimal performance. Final Testing: Conduct a load test to verify that the UPS can handle its rated capacity. Vertiv 10kVA UPS Testing Testing Procedures: Visual Inspection: Check for physical damage, loose connections, or corrosion. Battery Testing: Measure the voltage and capacity of the batteries. Conduct a discharge test to ensure batteries can hold a charge. Load Testing: Connect a load to the UPS and monitor its performance. Ensure that the UPS can supply power for the specified duration under load. Transfer Time Testing: Measure the time it takes for the UPS to switch from mains to battery power and back. Efficiency Testing: Assess the efficiency of the UPS under various loads to ensure it meets manufacturer specifications. Maintenance Recommendations Regular Maintenance: Schedule regular checks (at least annually) to ensure all components are functioning correctly. Battery Replacement: Replace batteries every 3-5 years, depending on usage and manufacturer recommendations. Firmware Updates: Keep the UPS firmware updated to benefit from the latest features and fixes. Conclusion Proper repair and testing of Vertiv 10kVA UPS systems are crucial for ensuring reliable power backup. Regular maintenance can prevent unexpected failures and extend the lifespan of the unit. If you require further details on specific models or repair services, feel free to ask!

Send Message