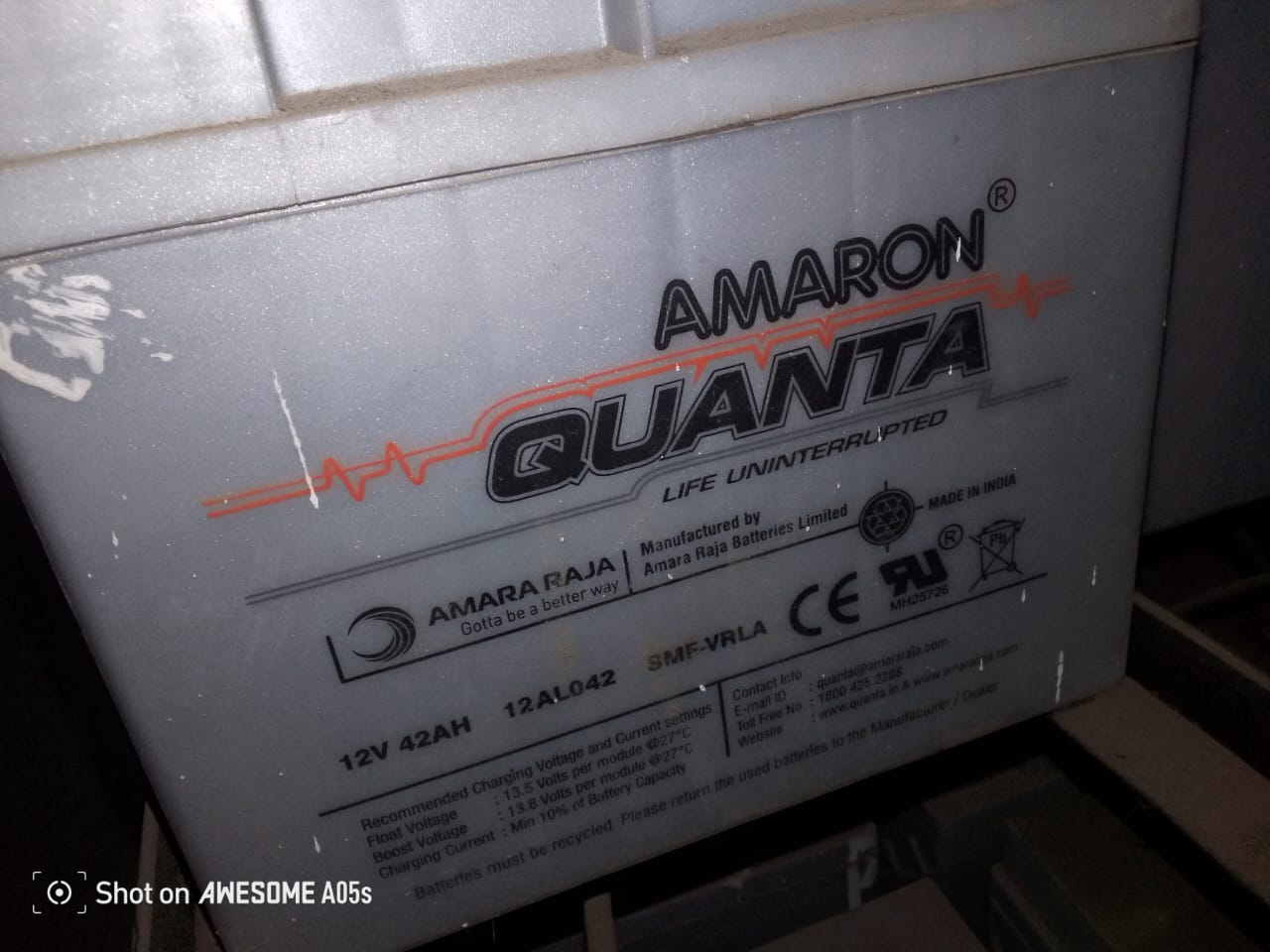

The Amaron Quanta 42Ah (Ampere-hour) battery is a high-performance, maintenance-free lead-acid battery designed for use in UPS systems, inverters, and solar energy storage applications. It provides reliable power backup for a range of devices, especially in environments where power stability and uninterrupted performance are crucial. Key Features of Amaron Quanta 42Ah Battery: Capacity: 42Ah (Ampere-hour) – This means the battery can provide 42 amps of current for one hour, or a proportionally smaller amount of current over a longer period of time, depending on the load. Technology: Maintenance-Free: The Amaron Quanta series batteries are sealed lead-acid batteries (SLA) that do not require frequent maintenance or water refilling, making them very convenient and hassle-free. High Performance: Designed for high efficiency, the Amaron Quanta 42Ah battery offers good charge retention, ensuring long-lasting backup for your UPS or inverter. Deep Cycle Battery: This is a deep-cycle battery, meaning it is designed to handle deeper discharges compared to regular car batteries. It is well-suited for applications where the battery may be discharged and recharged frequently. Durability: Long Shelf Life: Amaron Quanta batteries have a good shelf life and can perform well over extended periods when properly stored. High-Temperature Tolerance: They are built to withstand a wide range of temperatures, making them suitable for varying environmental conditions. Design: Compact and Reliable: The battery is designed to be compact, reliable, and easy to install, especially in environments where space is a concern. Vibration Resistant: The battery is engineered to resist damage from vibration, ensuring its durability in various settings. Safety Features: Flame-Retardant Materials: The Amaron Quanta 42Ah battery uses flame-retardant materials to ensure safety in case of battery malfunction. Leak-Proof: Being a sealed battery, it minimizes the risk of acid leakage, which adds an extra layer of safety. Application Areas: UPS Systems: Provides backup power to computers, servers, and networking equipment. Inverter Systems: Used in residential and small commercial applications to ensure uninterrupted power during outages. Solar Energy Storage: Can be used as part of a solar energy storage system to store excess energy generated during the day for use at night. Warranty: The Amaron Quanta batteries often come with a 2-year warranty, depending on the region and purchase conditions. It is recommended to check with the seller or manufacturer for specific warranty details. General Specifications: Voltage: 12V (standard for most UPS and inverter batteries). Capacity: 42Ah. Type: Sealed Lead-Acid (SLA) or AGM (Absorbent Glass Mat). Charging Voltage: Typically around 14.4 to 15.0V for 12V batteries. Nominal Voltage: 12V. Dimensions: Typically around length: 200mm, width: 165mm, height: 175mm (varies slightly depending on specific model). Weight: Approximately 12-14 kg. Maintenance Tips for the Amaron Quanta 42Ah Battery: Regular Charging: Always ensure that the battery is fully charged and avoid discharging it completely to extend its lifespan. Storage: If you’re storing the battery for an extended period, make sure to store it in a cool, dry place and check the charge level periodically. Clean the Terminals: Ensure the terminals are clean and free of corrosion. Clean the terminals with a mixture of baking soda and water if needed. Avoid Overcharging: Always use a compatible charger to avoid overcharging the battery, which could damage it. Check for Leakage: While the battery is sealed, it's a good idea to check for any leaks, especially if the battery has been in use for a long time or is showing signs of wear. Battery Testing: To check the health of the Amaron Quanta 42Ah battery, you can follow these steps: Voltage Check: Use a voltmeter to check the voltage. A fully charged 12V battery should show between 12.6V to 12.8V. Load Test: Under load, if the voltage drops rapidly below 10.5V for a 12V battery, it may be a sign of degradation. Capacity Test: If your application requires it, you can perform a discharge test to check the battery's capacity. This involves discharging the battery with a known load and measuring how long it takes for the voltage to drop below a certain threshold. Conclusion: The Amaron Quanta 42Ah battery is a reliable and durable option for providing backup power in various applications, including UPS systems, inverters, and solar power storage. It offers maintenance-free operation, a long service life, and excellent temperature tolerance. By regularly maintaining and testing the battery, you can ensure that it continues to perform effectively over time.

Send Message