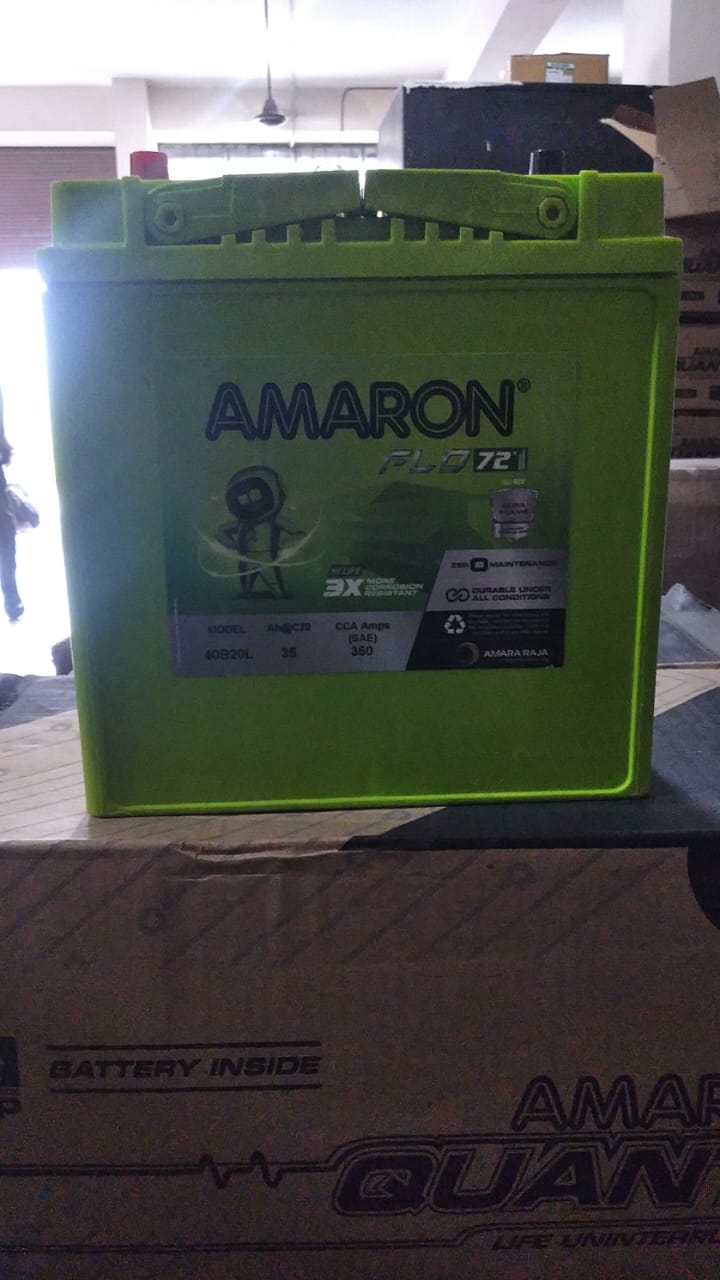

Battery Cells are the fundamental building blocks of batteries. They convert chemical energy into electrical energy through electrochemical reactions. Each cell typically consists of an anode, a cathode, an electrolyte, and a separator. Types of Battery Cells Lead-Acid Cells Components: Lead dioxide (cathode), sponge lead (anode), sulfuric acid (electrolyte). Characteristics: Voltage: Typically 2V per cell. Rechargeable: Yes (flooded, AGM, or gel). Applications: Automotive batteries, UPS systems, and backup power. Nickel-Cadmium (NiCd) Cells Components: Nickel hydroxide (cathode), cadmium (anode), potassium hydroxide (electrolyte). Characteristics: Voltage: 1.2V per cell. Rechargeable: Yes. Applications: Power tools, emergency lighting, and some medical devices. Nickel-Metal Hydride (NiMH) Cells Components: Nickel hydroxide (cathode), hydrogen-absorbing alloy (anode), potassium hydroxide (electrolyte). Characteristics: Voltage: 1.2V per cell. Rechargeable: Yes. Applications: Hybrid vehicles, rechargeable batteries for consumer electronics. Lithium-Ion (Li-ion) Cells Components: Lithium cobalt oxide or lithium iron phosphate (cathode), graphite (anode), lithium salt in organic solvent (electrolyte). Characteristics: Voltage: 3.6V to 3.7V per cell. Rechargeable: Yes. Applications: Smartphones, laptops, electric vehicles, and energy storage systems. Lithium Polymer (LiPo) Cells Components: Similar to Li-ion but use a polymer electrolyte. Characteristics: Voltage: 3.7V per cell. Rechargeable: Yes. Applications: Drones, RC vehicles, and portable devices due to lightweight and flexibility. Alkaline Cells Components: Zinc (anode), manganese dioxide (cathode), potassium hydroxide (electrolyte). Characteristics: Voltage: 1.5V per cell. Non-rechargeable (disposable). Applications: Household devices, flashlights, and remote controls. Zinc-Carbon Cells Components: Zinc (anode), manganese dioxide (cathode), ammonium chloride (electrolyte). Characteristics: Voltage: 1.5V per cell. Non-rechargeable (disposable). Applications: Low-drain devices like clocks and toys. Components of Battery Cells Anode: The negative electrode where oxidation occurs. Cathode: The positive electrode where reduction takes place. Electrolyte: A medium that allows ionic movement between the anode and cathode. Separator: A barrier that prevents direct contact between anode and cathode while allowing ionic flow. Characteristics of Battery Cells Voltage: The electric potential difference; varies by cell type. Capacity: Measured in Ampere-hours (Ah), indicates how much charge a battery can store. Energy Density: Amount of energy stored per unit volume or weight, typically measured in Wh/kg. Cycle Life: Number of charge/discharge cycles before capacity drops significantly. Self-Discharge Rate: Rate at which a battery loses its charge when not in use. Applications of Battery Cells Consumer Electronics: Smartphones, laptops, tablets. Automotive: Electric vehicles, hybrid vehicles, starting batteries. Industrial: Forklifts, backup power for servers and telecommunications. Renewable Energy: Solar energy storage systems and grid storage. Portable Devices: Cameras, drones, and power tools. Conclusion Battery cells are essential components in various applications, providing energy storage and supply. Understanding the types, characteristics, and applications helps in selecting the right battery for specific needs. Always consider factors like voltage, capacity, and intended use when working with batteries.

Send Message