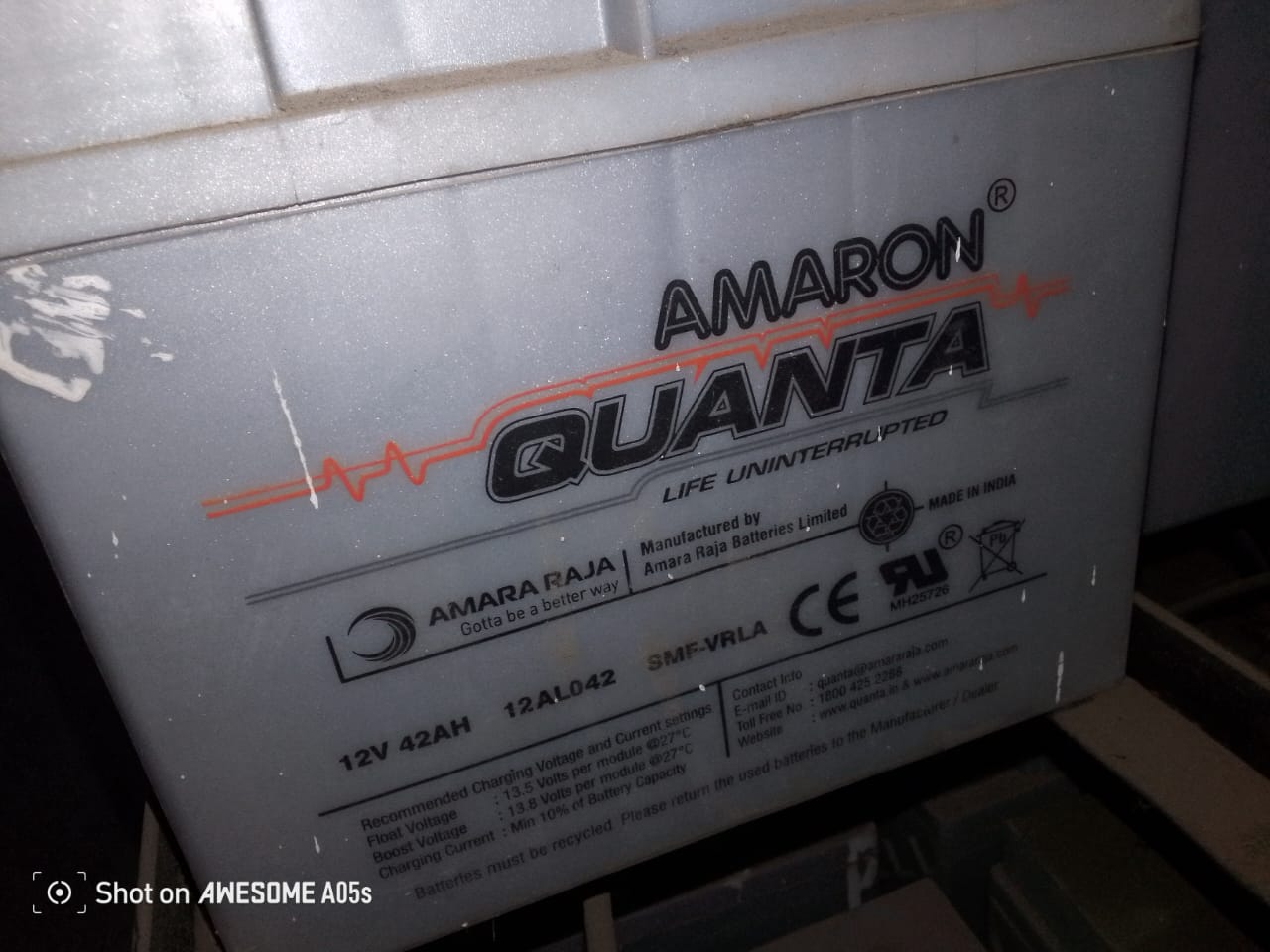

Amaron batteries are well-known for their performance and reliability in various applications, including automotive, UPS systems, and renewable energy setups. Here’s a comprehensive overview of charging Amaron batteries, covering methods, parameters, and best practices. Charging Amaron Batteries 1. Charging Methods: Constant Current (CC) Charging: The charger supplies a constant current until the battery reaches a predefined voltage. Commonly used for lead-acid batteries, ensuring a safe and efficient charge. Constant Voltage (CV) Charging: After reaching the target voltage, the charger maintains that voltage while the current decreases. This method is suitable for maintaining battery charge without overcharging. Smart Chargers: These chargers automatically adjust voltage and current based on the battery's state. They often include features like temperature compensation and multi-stage charging. 2. Charging Parameters: Voltage: For lead-acid Amaron batteries, the charging voltage typically ranges from 2.25V to 2.40V per cell. For a 12V battery (6 cells), this translates to about 13.5V to 14.4V. Current: The charging current should be set to 10-30% of the battery's capacity (C-rate). For example, a 100Ah battery should be charged at 10A to 30A. Temperature Compensation: Adjust the charging voltage based on the ambient temperature to avoid damage. Generally, for every degree Celsius above 25°C, reduce the charging voltage by 0.005V per cell. 3. Charging Stages: Bulk Charge: The initial phase where maximum current is applied to quickly charge the battery. This stage continues until the battery reaches approximately 70-80% of its capacity. Absorption Charge: The charger maintains a constant voltage, allowing the current to taper off as the battery approaches full charge. This phase ensures the battery reaches full capacity without overcharging. Float Charge: A lower voltage is maintained to keep the battery fully charged without overcharging. This is essential for maintaining the battery in a ready state for immediate use. Best Practices for Charging Amaron Batteries: Use the Right Charger: Always use a charger specifically designed for the type of battery you are charging (lead-acid, AGM, etc.). Avoid Deep Discharge: Regularly charge the battery to prevent deep discharges, which can shorten battery life. Monitor Temperature: Ensure the charging environment is within the recommended temperature range (typically 15°C to 25°C). Regular Maintenance: Periodically check the battery's state of charge and electrolyte levels (if applicable). Clean terminals and connections to ensure efficient charging. Follow Manufacturer Guidelines: Always refer to the specific charging instructions provided by Amaron for the particular battery model. Conclusion Proper charging of Amaron batteries is vital for maximizing their lifespan and performance. By following the recommended charging methods, parameters, and best practices, users can ensure that their batteries operate efficiently and reliably. If you have specific models in mind or need further details, feel free to ask!

Send Message