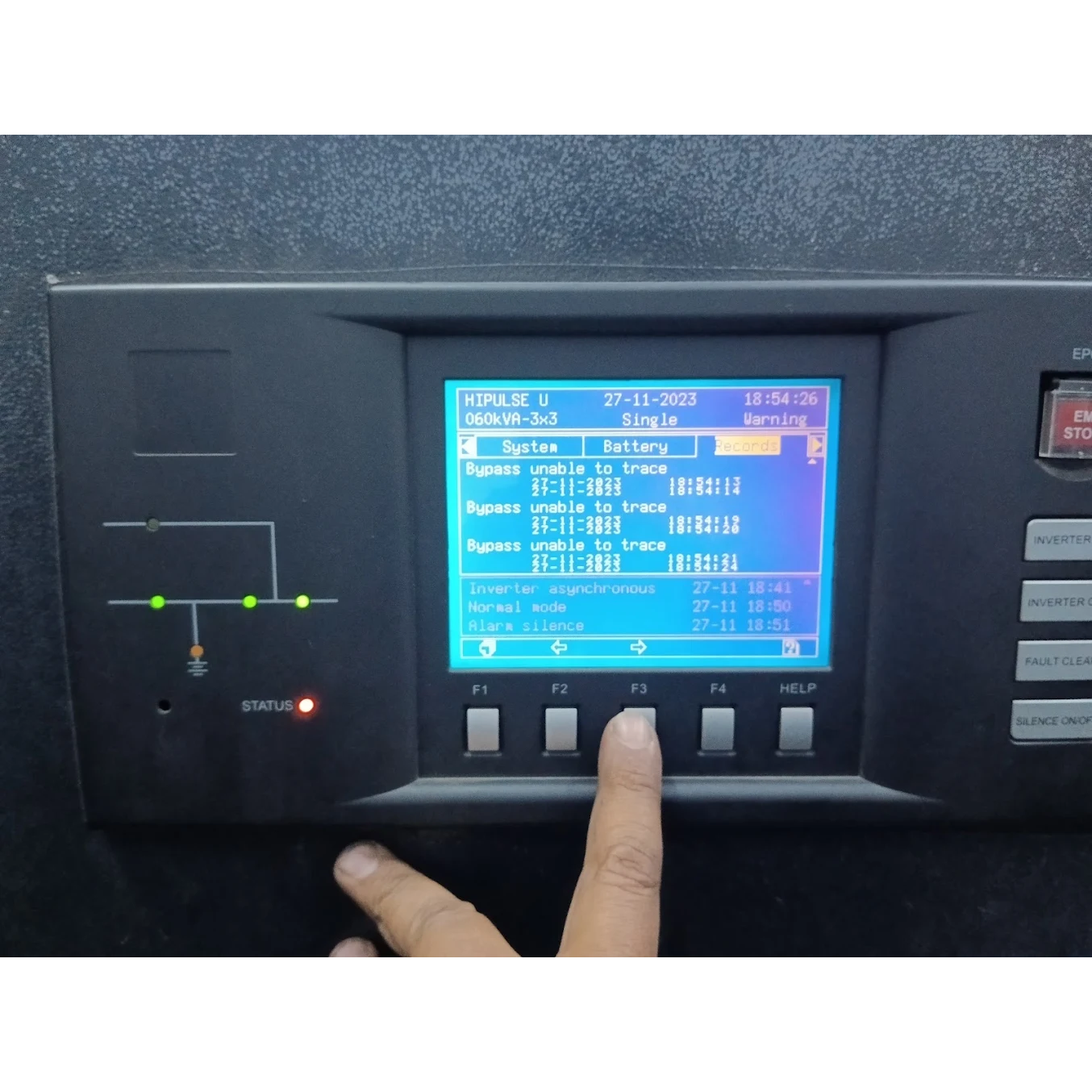

Vertiv Ups Testing

Testing a Vertiv UPS (Uninterruptible Power Supply) is crucial to ensure its reliability and performance in providing backup power during outages. Here are the key aspects and procedures involved in Vertiv UPS testing:

1. Acceptance Testing

Purpose: Conducted upon installation to verify that the UPS meets specified performance criteria.

Procedure:

Inspect physical installation and connections.

Verify input/output voltage and frequency.

Check battery connections and integrity.

Perform a load test to ensure the UPS can handle the specified load.

2. Load Testing

Purpose: To assess the UPS's ability to support its rated load.

Procedure:

Connect a known load to the UPS.

Monitor performance for a specified duration (usually 30 minutes to several hours).

Measure output voltage, frequency, and total harmonic distortion (THD).

Check for any alarms or faults during the test.

3. Battery Testing

Purpose: To evaluate the health and capacity of the UPS batteries.

Procedure:

Conduct a capacity test to determine the remaining runtime under load.

Measure individual cell voltages and overall battery condition.

Perform a discharge test to assess battery performance under load.

Inspect for physical signs of wear, corrosion, or leakage.

4. Functional Testing

Purpose: To ensure all UPS features and functions operate correctly.

Procedure:

Test the transfer time from utility to battery power.

Verify alarm and notification systems.

Check communication interfaces (e.g., SNMP, USB) for proper operation.

Test any additional features, such as power management software.

5. Regular Maintenance Checks

Purpose: To ensure ongoing reliability and performance.

Procedure:

Schedule periodic inspections (monthly, quarterly, or annually).

Clean dust and debris from the UPS and surrounding area.

Tighten electrical connections and inspect for signs of wear.

Review event logs and diagnostic data for any anomalies.

6. Documentation and Reporting

Purpose: To maintain a record of testing and maintenance activities.

Procedure:

Document all test results, including any issues found and corrective actions taken.

Maintain a log of battery replacements and other significant maintenance activities.

Provide reports to stakeholders for compliance and operational reviews.

Conclusion

Regular testing and maintenance of Vertiv UPS systems are essential to ensure they function correctly when needed. Following these testing procedures helps identify potential issues before they lead to failures, ensuring continuous power protection for critical systems. For specific testing protocols, refer to the Vertiv user manual or consult with a certified technician.

Keywords

30 minutes

load inspect

physical signs

capacity test

load test

certified technician

function correctly

corrective actions

issues found

reporting purpose

anomalies 6 documentation

diagnostic data

additional features

snmp usb

transfer time

ups features

wear corrosion

remaining runtime

upss ability

ups meets

procedures involved

key aspects

test results

discharge test

critical systems

integrity perform

battery replacements

ensure ongoing reliability

assess battery performance

ups monitor performance

vertiv ups systems

battery condition perform

proper operation test

vertiv user manual

annually clean dust

providing backup power