Vertiv Ups Repairing

Repairing uninterruptible power supplies (UPS) involves a series of steps to diagnose and fix issues, ensuring they operate reliably. Here’s a comprehensive overview of the UPS repair process, common issues, and considerations:

UPS Repair Process

Initial Assessment

Identify Symptoms: Gather information on the symptoms or problems, such as failure to start, battery issues, or alarms.

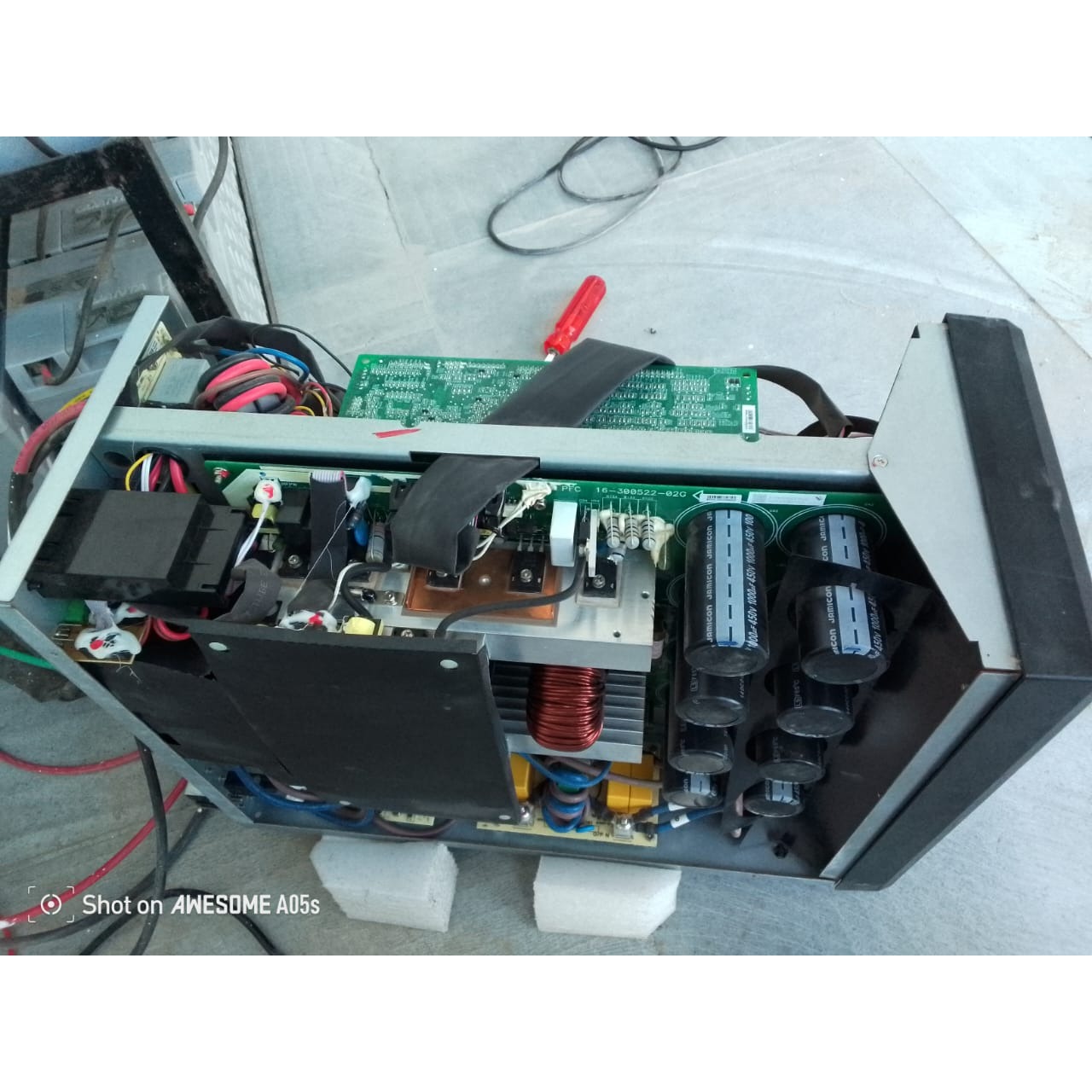

Visual Inspection: Check for any visible damage, such as burned components, corrosion, or loose connections.

Diagnosis

Self-Diagnostics: Utilize built-in self-test features, if available, to diagnose issues.

Multimeter Testing: Measure voltage, current, and resistance to identify electrical issues.

Battery Testing: Check the health of the batteries using a battery tester or multimeter.

Check Fuses and Circuit Breakers: Ensure all fuses and breakers are intact and functioning.

Common Issues

Battery Failure: Batteries may need replacement due to age or over-discharge.

Capacitor Issues: Capacitors can fail due to heat or age, leading to performance issues.

Cooling Problems: Blocked fans or insufficient ventilation can cause overheating.

Control Board Malfunctions: Issues with the control board can affect the UPS\'s operation.

Input/Output Issues: Problems with input power or output voltage can indicate faults in the UPS circuitry.

Repair and Replacement

Battery Replacement: Remove and replace old batteries with new ones of the same specifications.

Component Replacement: Replace faulty capacitors, fuses, or other components as diagnosed.

Resoldering Connections: Fix any broken or loose solder joints on the circuit board.

Software/Firmware Updates: If applicable, update the UPS firmware to ensure optimal performance.

Testing After Repair

Functional Testing: After repairs, perform a complete functional test of the UPS.

Load Testing: Test the UPS under load to ensure it can handle the required capacity.

Battery Cycle Testing: Run the UPS on battery power to check for proper operation.

Final Inspection

Safety Check: Ensure all repairs meet safety standards.

Documentation: Document the repairs, parts replaced, and any other relevant information for future reference.

Maintenance Tips

Regular Testing: Conduct regular self-tests and inspections to catch issues early.

Battery Maintenance: Check battery connections and terminals periodically; keep them clean and tight.

Environment Control: Ensure the UPS is kept in a cool, dry environment to extend its lifespan.

Firmware Updates: Keep the UPS firmware updated for improved performance and security.

Professional Repair Services

When to Seek Help: If the issue is beyond basic troubleshooting or involves complex repairs, it’s best to consult a professional.

Authorized Service Centers: Consider using authorized repair services for specific brands to ensure quality repairs.

Conclusion

Repairing a UPS requires careful diagnosis, knowledge of electrical systems, and attention to safety. Regular maintenance can help prevent many issues, ensuring your UPS remains reliable in providing backup power when needed. For complex repairs, professional services are recommended to ensure the job is done safely and effectively.

Keywords

new ones

Vertiv Ups

many issues

input power

UPS firmware

Load Testing

Blocked fans

backup power

old batteries

UPS circuitry

common issues

circuit board

battery power

output voltage

battery issues

visible damage

battery tester

quality repairs

complex repairs

Battery Failure

specific brands

Regular Testing

Battery Testing

Cooling Problems

proper operation

Circuit Breakers

Capacitor Issues

Maintenance Tips

future reference

safety standards

other components

careful diagnosis

faulty capacitors

electrical issues

required capacity

burned components

loose connections

Visual Inspection

performance issues

Multimeter Testing

electrical systems

regular self-tests

self-test features

Initial Assessment

UPS repair process

Battery Replacement

Input/Output Issues

Regular maintenance

optimal performance

same specifications

battery connections

Battery Maintenance

Environment Control

loose solder joints

improved performance

Component Replacement

basic troubleshooting

professional services

Battery Cycle Testing

cool, dry environment

comprehensive overview

Resoldering Connections

insufficient ventilation

complete functional test

Software/Firmware Updates

Repair Functional Testing

other relevant information

Control Board Malfunctions

authorized repair services

Authorized Service Centers

Professional Repair Services

Final Inspection Safety Check

uninterruptible power supplies