All Types Of Ups & Batteries Repair And Maintenance Of Ups

Repair and maintenance of UPS (Uninterruptible Power Supply) systems and batteries are crucial for ensuring their reliability and longevity. Below is a comprehensive overview of the types of UPS systems, batteries, and the associated repair and maintenance practices.

Types of UPS Systems

Offline/Standby UPS:

Description: Provides basic protection; switches to battery during a power outage.

Maintenance: Regular battery checks and replacement every 3-5 years.

Line-Interactive UPS:

Description: Offers voltage regulation and battery backup; ideal for environments with frequent voltage fluctuations.

Maintenance: Inspect and test the battery and inverter regularly; check for dust accumulation.

Online Double-Conversion UPS:

Description: Provides continuous power and isolates equipment from power issues.

Maintenance: More complex; requires regular inspection of internal components, battery health checks, and firmware updates.

Modular UPS:

Description: Scalable systems that allow for adding or removing modules based on power needs.

Maintenance: Regular checks on each module, ensuring proper connections and functionality.

Types of Batteries Used in UPS

Lead-Acid Batteries:

Types: Sealed Lead Acid (SLA), Absorbent Glass Mat (AGM), Gel.

Maintenance: Regularly check electrolyte levels (for non-sealed types), clean terminals, and test for capacity.

Lithium-Ion Batteries:

Description: Increasingly used due to longer life and lighter weight.

Maintenance: Monitor battery management systems (BMS) for health and performance; check for firmware updates.

Nickel-Cadmium (NiCd) Batteries:

Description: Used in specific applications; known for durability.

Maintenance: Regularly test for capacity and perform equalization charging.

Repair and Maintenance Practices

1. Routine Inspections

Visual Checks: Inspect for physical damage, corrosion, or loose connections.

Environmental Conditions: Ensure the UPS and batteries are in a suitable environment (temperature, humidity).

2. Battery Maintenance

Testing: Conduct regular load tests and capacity tests to assess battery health.

Cleaning: Clean terminals and connections to prevent corrosion.

Replacement: Replace batteries as per manufacturer recommendations (typically every 3-5 years for lead-acid).

3. UPS Maintenance

Firmware Updates: Keep the UPS firmware updated for optimal performance.

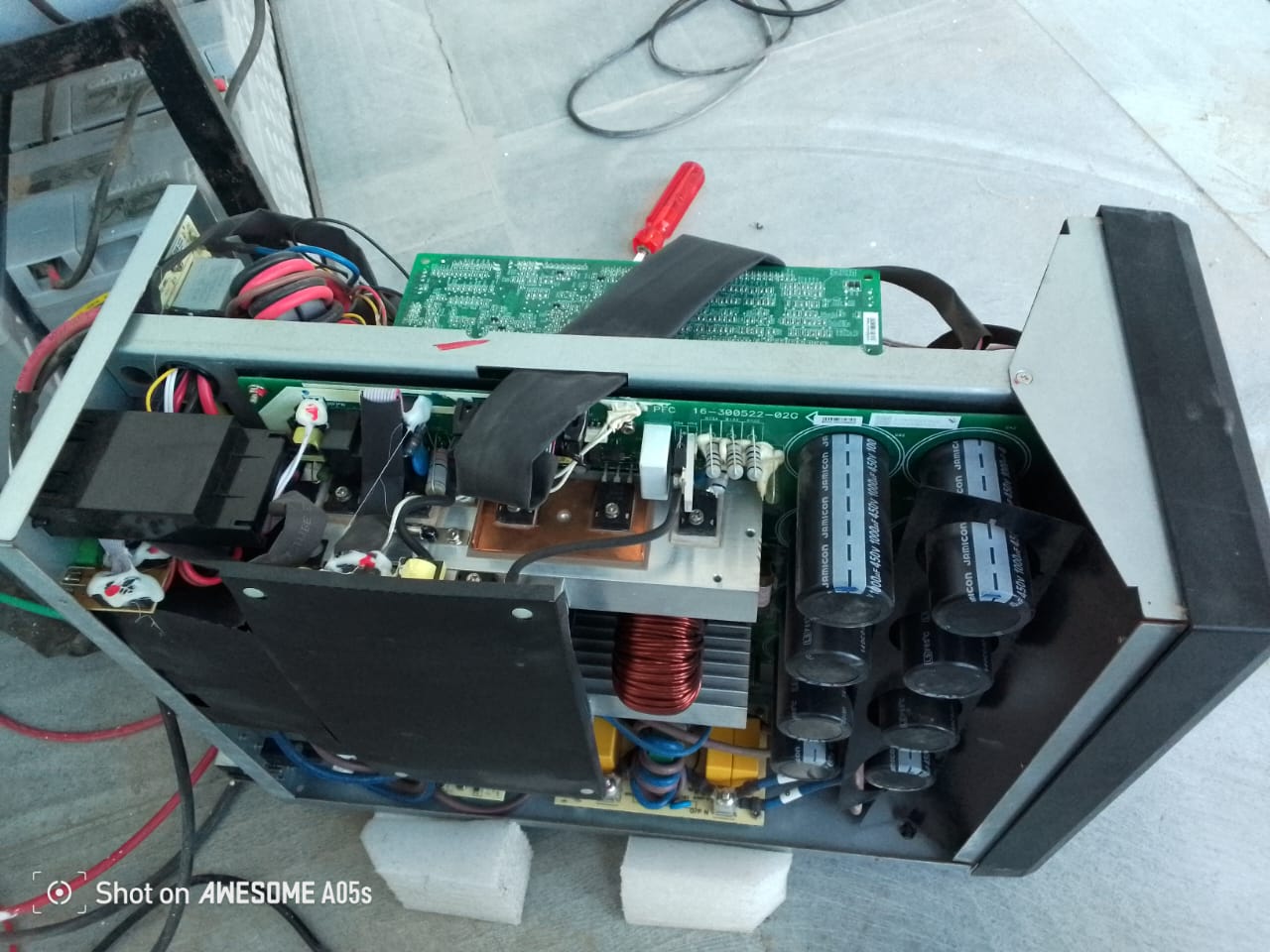

Component Checks: Inspect capacitors, fans, and other internal components for wear and tear.

Cooling System: Ensure that cooling fans are operational and that vents are not blocked.

4. Emergency Procedures

Testing: Regularly test the UPS under load conditions to ensure it functions correctly during an outage.

Documentation: Maintain records of all maintenance activities, repairs, and battery replacements.

5. Professional Servicing

Scheduled Maintenance: Engage professional services for comprehensive inspections and repairs, especially for complex systems like online UPS.

Emergency Repairs: Have a plan in place for rapid response to UPS failures, including access to spare parts.

Conclusion

Regular maintenance and timely repairs of UPS systems and batteries are essential for ensuring uninterrupted power supply and protecting sensitive equipment. By following a structured maintenance schedule and engaging professional services when necessary, you can significantly extend the lifespan and reliability of your UPS systems and batteries.

For specific service providers or detailed maintenance plans, consider reaching out to local UPS service companies or manufacturers for tailored solutions.

Send

Message