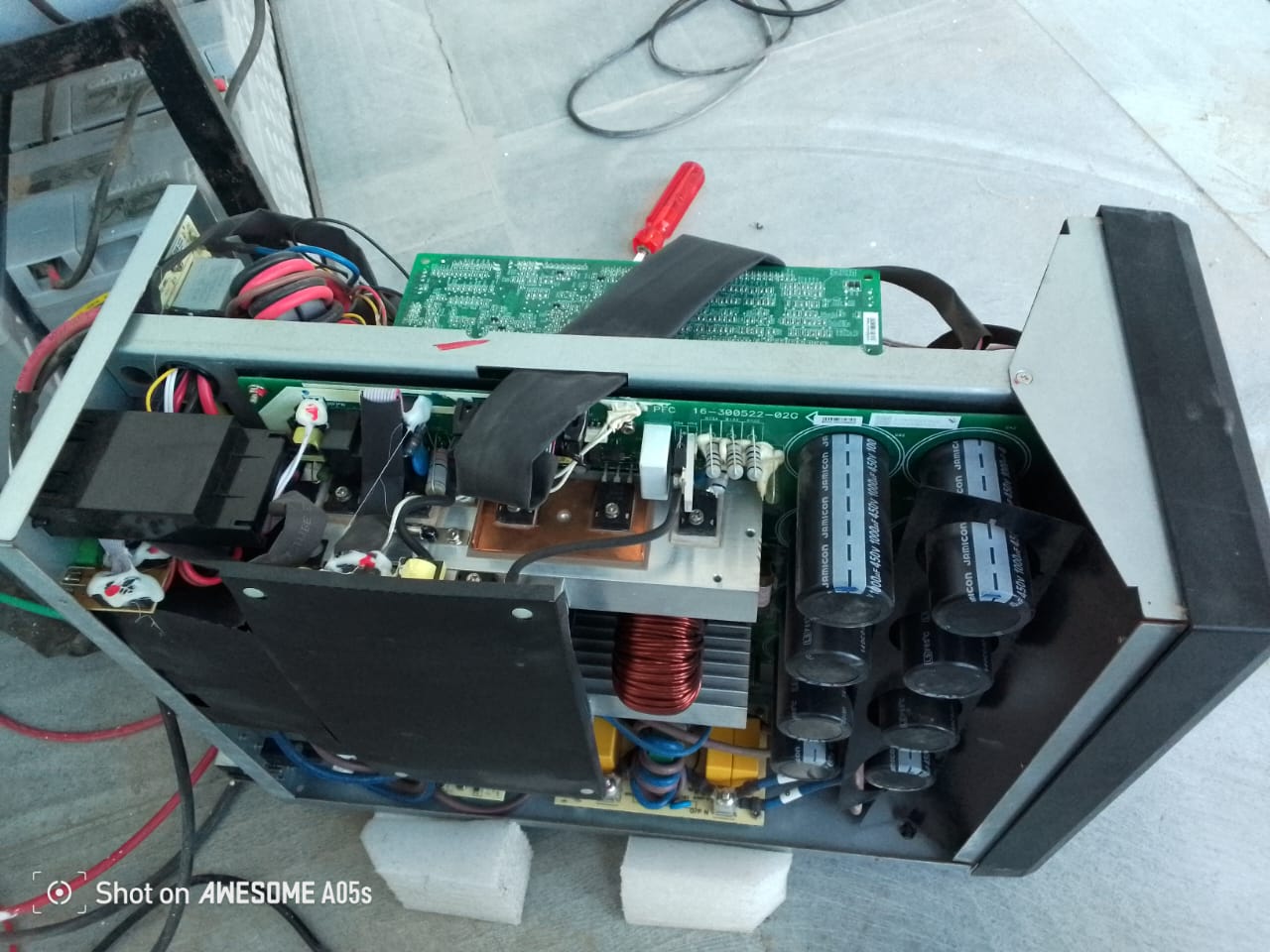

Repairing and testing an APC UPS (Uninterruptible Power Supply) involves several steps to diagnose issues and ensure the unit functions properly. Here’s a detailed guide on how to approach this: Common Issues with APC UPS Battery Failure: Most common issue; symptoms include frequent beeping and inability to hold a charge. Overload: The UPS may beep continuously if connected devices exceed its capacity. Faulty Output: No power output despite being plugged in. Firmware Issues: May require updates or resets. Tools Needed Multimeter Screwdriver set Replacement batteries (if needed) Laptop or PC for firmware updates Diagnostic software (if applicable) Testing Procedure Visual Inspection: Check for physical damage, burnt components, or loose connections. Inspect the battery for any signs of swelling or leakage. Battery Testing: Disconnect the UPS from the wall outlet. Use a multimeter to measure the battery voltage. Compare it to the rated voltage (e.g., 12V for most lead-acid batteries). If the voltage is significantly lower, consider replacing the battery. Load Testing: Connect a load tester to the UPS and apply a known load (within the UPS capacity). Monitor the output voltage and see if it remains stable under load. Output Testing: Plug the UPS into the wall and turn it on. Measure the output voltage with a multimeter to ensure it’s delivering the correct voltage (typically around 120V or 230V depending on your region). Check if the UPS switches to battery mode when you disconnect it from the wall. Overload Testing: Gradually increase the load on the UPS until it beeps or shuts down. Verify that it returns to normal operation once the overload is removed. Repair Procedures Battery Replacement: Follow the manufacturer’s guidelines for replacing batteries. Dispose of old batteries responsibly. Firmware Updates: Connect the UPS to a computer. Use APC’s software (like PowerChute) to check for and install firmware updates. Component Repair: If internal components (like capacitors or fans) are damaged, soldering skills may be required for repairs or replacements. Reassembly: Carefully reassemble the UPS, ensuring all screws are tightened and no wires are pinched. Final Testing After repairs, conduct a full load test to ensure the UPS operates correctly under stress. Monitor for any unusual noises or overheating during operation. Safety Precautions Always ensure the UPS is unplugged before performing internal inspections or repairs. Handle batteries with care, as they can be hazardous. Conclusion Regular testing and maintenance of your APC UPS can extend its lifespan and ensure reliable performance. If issues persist after self-repair attempts, consider consulting a professional technician or contacting APC support for assistance.

Send Message